Mechanical Capabilities

- Mechanical Requirements Development

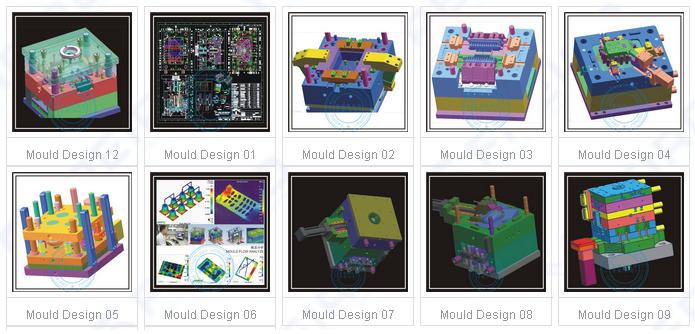

- 2D/3D CAD layout

- Piece-part Design and assembly

- Rapid Prototyping of mechanical parts

- Integration with electronic components

- Test and Design verification

- Tooling support

- Certification Documentation

- Transfer to Production Documentation

Enclosure Design

Our Mechanical Design team has developed dozens of enclosures for a wide variety of electronics including handheld devices, ruggedized enclosure for aerospace applications, sensors, and gaming equipment. The project steps start with your ideas and visions. This turns into an industrial design, followed by detailed mechanical drawings and then rapid prototypes. Of course, there are review milestones at every step along the way to make sure that the design is progressing as you intended. Final Mechanical designs move into production with ease as the RightHand team produces all of the documentation required to manufacture your products.

Our team is used to rugged environments and stringent agency requirements on materials, weights, emissions, and thermal requirements. We keep these in mind at the concept phase to ensure that the end product meets all of your certification needs.

EMI and ESD Designs

Achieving agency approvals and certifications require that the full product has no emissions issues. EMI and ESD problems can commonly halt testing and ultimately delay product release by weeks or even months. The solutions to most emissions problems can be either electronics changes, software changes, or mechanical changes. Mechanically, EMI leakage can sometimes be corrected with enclosure design changes, including adding gaskets, materials coating or shielding. The engineering teams will work together to find the most rapid, cost effective correction to emissions issues, should they occur.

Thermal Heat Dissipation Design

When a mechanical project involves a ruggedized metal enclosure designed to protect the electronics from the external elements, a new set of issues crop up. What do we do with the heat generated inside the enclosure by the enclosed electronics? The mechanical team has solved this issue many times, creating unique fan-less systems that fit the environment. Our design solutions include heat sinks and custom enclosures that dissipate heat, as well as compartmentalizing structures to direct air flow and keep key electronics cool.

Materials Recommendations mechanical engineers offer their years of experience and expertise to your team by making recommendations on materials for product design. Our seasoned engineers will help you understand the tradeoffs between cost, durability, heat tolerance, weight and other factors that come into play when designing product enclosures and heat dispersion elements. They will help make sure that the final mechanical design meets all of your requirements and will help your products achieve certifications.

Injection molding for ABS, AS, PP, POM,PA6, PA66, PC, PMMA, NYLON, HDPE,PVC,HIPS, TPU and TPR and so on

We provide one-stop new product innovation, design, development, quality control, manufacturing and shipment services (Including related logistical & custom services), electronic product wholesale and import & export, related outsourcing services and so on.

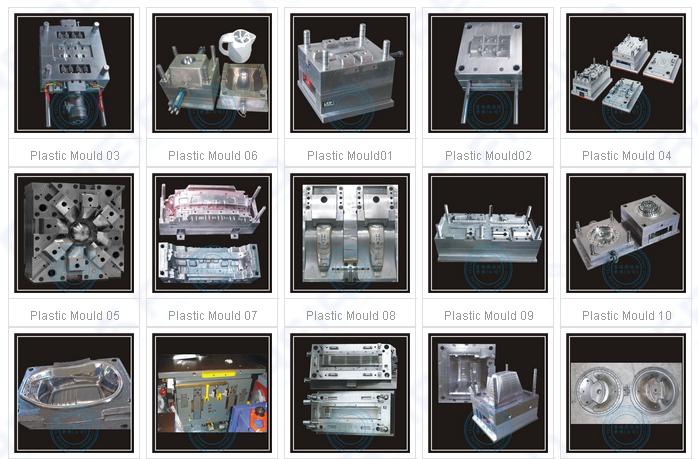

Plastic Mould

Metal Mould

Specification include:

◆Cavity material (Cavity & Core Steel) □H13 □GS738H □Others;

◆Mould base material: □S50C/1050 □P-20 □Others;

◆ Number of cavity:

◆ Part material:

◆ Product tolerance:

◆ Cavity & core heart hardness: □Ordinary □Reinforce;

◆ Mould structure: □Hot runner mould □3-plate mould □2-plate mould □Others;

◆ Hot runner system: □DME □Husky □YUDO □Synventive □Others;

◆ Surface texture treatment:

◆ Sprue type: □Edge gate □Submarine gate □Pin-point gate 口Direct gate 口Others;

◆ Ejection system: □Ejector pin □Ejector sleeve □ Stripper □Gas ejector □Other;

◆ Cavity & core Finish:

◆ Mould Life Expectancy :

◆ Processing period

1 Engineering & Technical: Mould Design, Mould Flow Analysis, Product Design, Project Management, Design for Manufacturing, etc.

2 Mould Building: Mould size up to 15 Tons, Assembly, Fixtures, Hot-Runner Capability;

3 Injection Molding: 80 Through 1000 Ton Injection Molding Presses

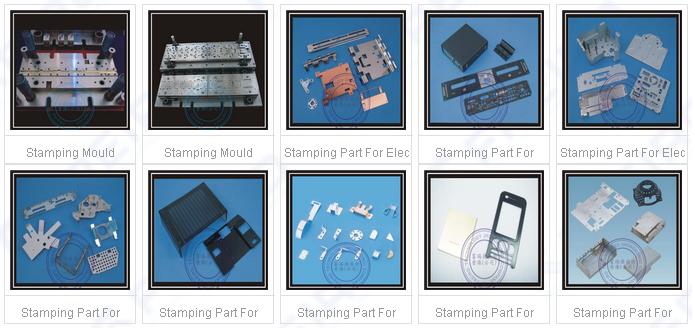

4 Secondary Operations: CNC Machining, Sonic Welding, Heat Staking, Hot Stamping, Pad Printing, etc.

5 Finishing: Water Based Paint, Powder Coat Paint, Spray on Shielding, Product Assembly, etc.

Quality Policy

The Quality Policy is established and structured to provide ISO 9001:2000 compliant quality management. We get the defect-free products, on-time delivery and finest after-service by all staff participation, the whole process control and general improvement.

Q&A

1.What is your Scope of business?

A. Precision Plastic Mold manufacture

B. Medium and large plastic mold manufacture

C. Injection molding

D. professional connectors designing and making

E. R&D service

F. Metal stamping parts

2. How about the tolerance?

Mold tolerance is 0.005 mm, Product tolerance is 0.02 mm.

3. What steel do you usually use

We usually use steel of P20, P20H, H-13,O-1,S-7,420,420H,D2, NAK80, 1.2311, 1.2711 1.2344 1.2510 1.2083 1.2316 and 1.2379.

4.What standard components do you usually use?

We use standard components from LKM, DAIDO, HASCO, DME. (Hot Runner: MOLD MASTER HUSKY DME HASCO INCOE THERMOPLAY YUDO.)

5. How do you make a quotation?

RE: Majority of mould costs are materials and machining costs. What follows is that the products’ structure, materials used, number of cavities, and mould size influence the price mostly. We can make a quotation on the basis of that we know all of those mentioned. For this reason, we provides a detailed calculation of all the costs on quoting. We have specialists in making quotation, and they have 15 years of experience on mould design and mould making.

6. What is the life expectancy of moulds?

RE: Mould life depends on the kind of tooling steel, the precision of mould building and mould maintenance quality during production. Usually plastic injection moulds can stand without a problem 300 thousand shots and die casting moulds 80 thousand shots. The life expectancy can be lengthened or shortened by choosing appropriate steel. we guarantee mould life.

Product Warranty and Technical Support.

Our delivery has mass producing quality assurance. We warrants our products against manufacturing defects for a period of one year from date of shipment to the original purchaser, and offers software updates lifetime to registered customers free of charge. We have an experts team to provide technical support.

We have been running 8 years, this is our license from Chinese government website:

http://www.sgs.gov.cn/LicenceView/Id=20120530152953117

We have served 1000+ customers from 100+ countries all over the world, Please find a list of part of our customers here:

http://www.quickembed.com/Tools/Shop/Customer/Index.html

We can provide contact if you want a reference.

We are looking for sell/retail/ditribute/channel partners in all over the world.

You are encouraged to share your information in the forum, share your business information, share your success, it will get you more business and success!

If you need some partner, technical, hardware, software, marketing, channel, sales, just post your message on the forum, because someone in the world may be finding you!

Our world and technology is changing and growing so fast that no one no single company can do all work, clever people can get information from the web and try to make it but will take a lot time to learn, we need cooperation!

Promote your product in the forum, or just an idea, don't be afraid other will copy, there are similar products and ideas all over the world, the only difference is who will make it real in a right time in success!

If you want more formal, list your product in our web catalog, to promote it to all over world, we are open, please send email to us.

We can build a prototype sample very fast, for you, to demonstrate, to your customer.

A demo is much more powerful than a thousand words!

It will save you a lot of valuable time!

Make a concrete step from good idea to real success!

We help you succeed, providing ARM Embedded Quick Demo.

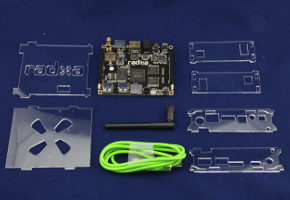

ODM/OEM Service

Layout, for special defined interface and resize the board for your requirements.

Product prototyping, sourcing accessories for your product requirements.

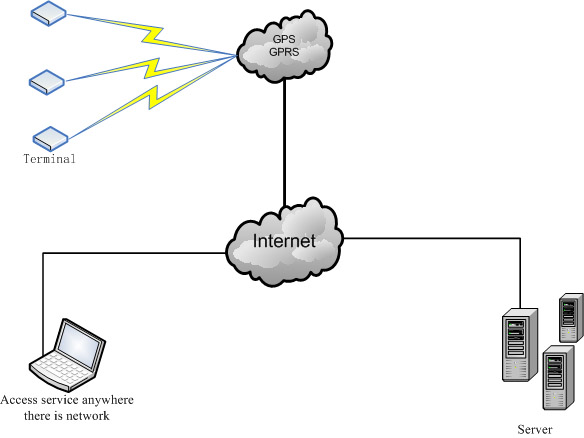

Recommend GPS module, GSM/GPRS module with communication software.

Software Developing.

Sourcing solution and turn key to you.

You might have interest to know what products this board makes, please send us an email to know more product design cases. Embedded pc computer system has broad usge, some examples:

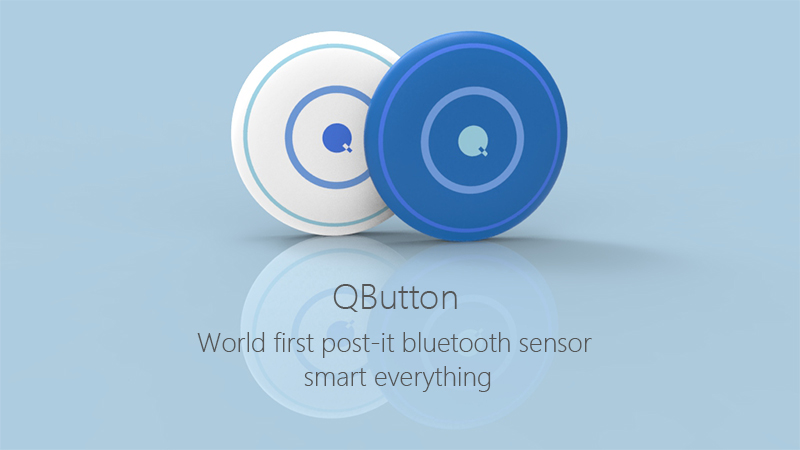

QButton, world first post-it bluetooth sensor, open data, customize for your usage.

Popular bluetooth v4.0 ble sensor tag, smart devices, wearable electronic computer.

Palm size desktop computer.

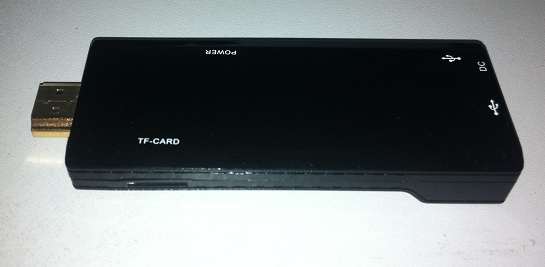

U-disk size computer

Android 4.0 5inch 7inch capacitive touch pad

9D position pose system digital compass

GPS, Compass and accelerator in one tiny module.

GPS GPRS LBS solution.

Navigate Locate Track Solution, Location Based Service

Robot Motor Medical Testing System

One motor control board controlling 9 motors at the same time

Robot arm move and grab.

12" to 15" size multimedia or HMI solution, fixed on wall or desk or large vehicle:

Backside:

10" solution, fixed in car:

7" solution, fixed in car:

more 7inch cases here:

http://www.quickembed.com/Tools/Shop/Solution/201001/67.html

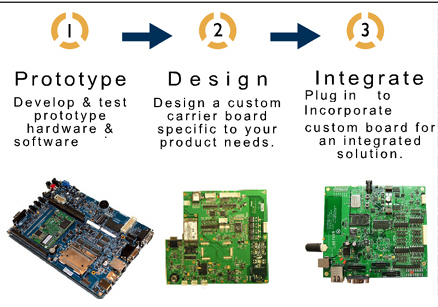

Using SBC is as easy as 1,2,3; simply prototype and test your development using a suitable SBC, then design your custom connector board and finally build your product.

The advantage of SBC is that when you define a new product, you have only small change on baseboard/motherboard, no change on SBC/daughter board, it saves great effort, and save much expense as the SBC is big lots produced while baseboard can be produced in small lots, also this helps improving the quality of your products.

Read more about arm board customize design odm service.

Read more about arm linux driver and application software develope.

Our mission is to provide quick start and easy use embedded platforms for maximize customers productivity. If you find any platform more competitive than ours, please do let us know. We can improve our product for you.

Those who want to list your product here in this web and sell to worldwide customers, please contact us.

-- Stay Hungry. Stay Foolish. Memory of Steve Jobs.

-- Dream bigger, Love Deeper, Live Longer! :-)

|